Our Materials

Metallic Glass

Metallic glass is an emerging class of metals having an “amorphous” atomic structure, which promotes unusual properties making it attractive for manufacturing advanced engineering hardware.

o Stronger than high performance steel

o Hard like ceramic

o Moldable like plastic

Engineering Alloys

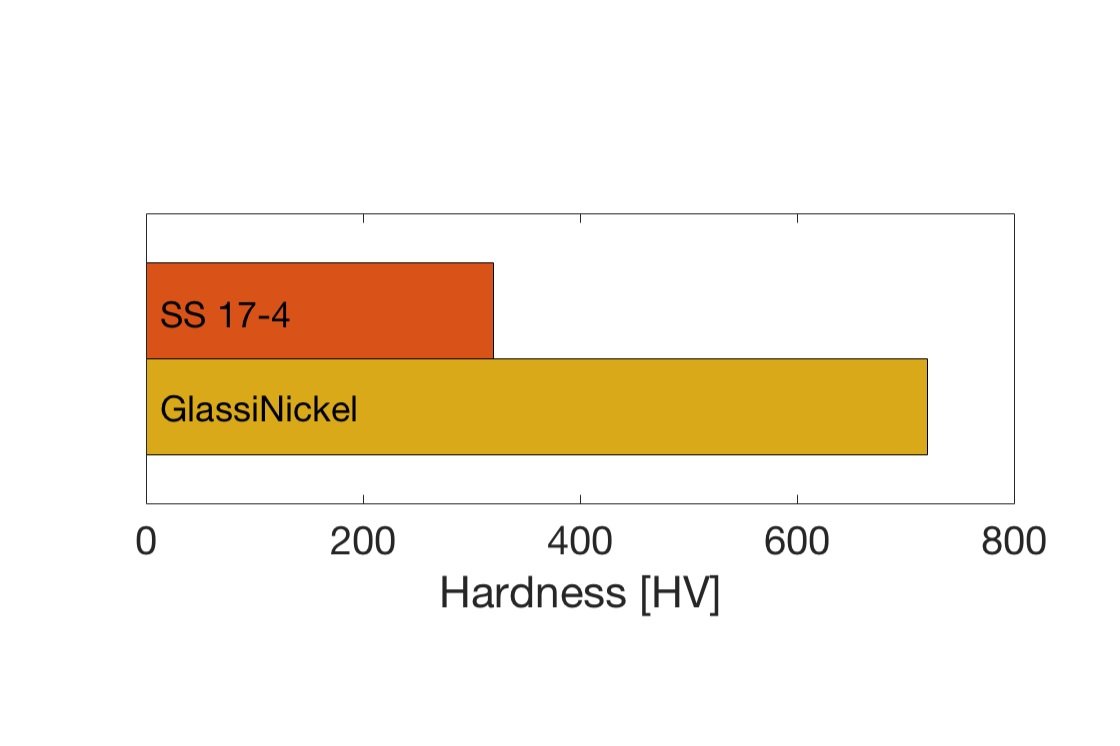

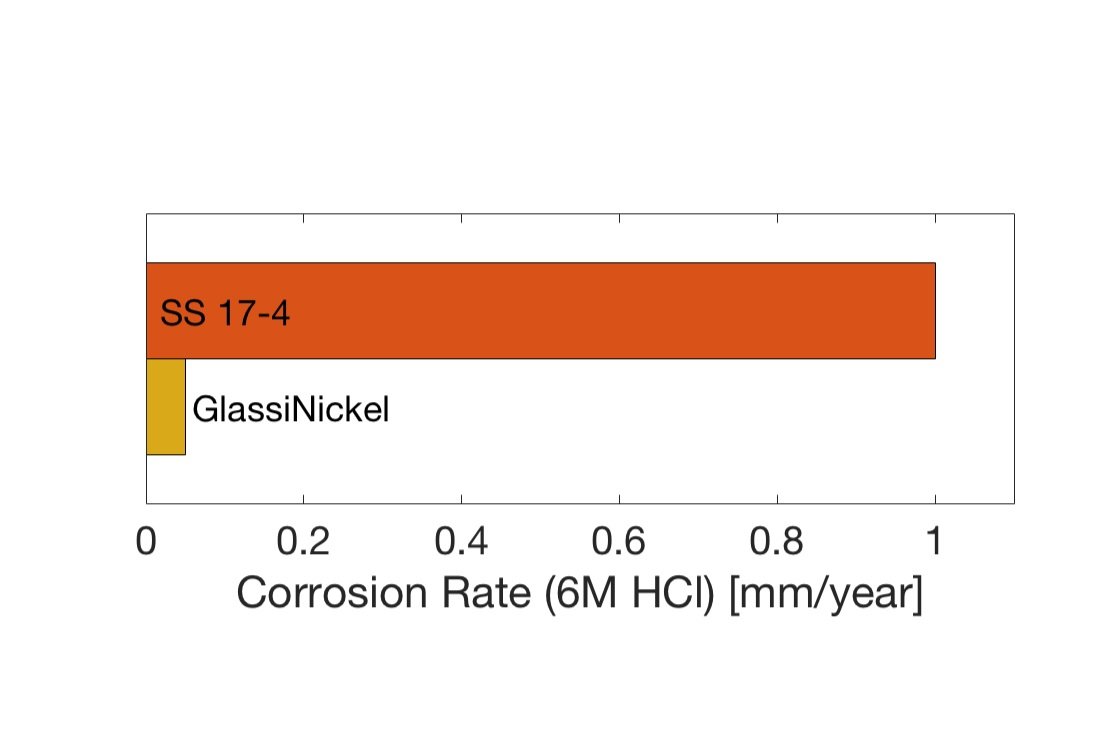

Glassimetal’s proprietary engineering alloys deliver performance by offering superior strength and hardness, corrosion and wear resistance.

GlassiNickel

GlassiNickel is a nickel-chromium based metallic glass that offers ultrahigh strength and hardness combined with unparalleled corrosion resistance. With a competitive materials cost, GlassiNickel is uniquely suited for small complex engineering hardware that require extreme performance in harsh environments.

Applications: orthodontics, surgical hardware, medical devices, mechanical watch components, robotic motion systems

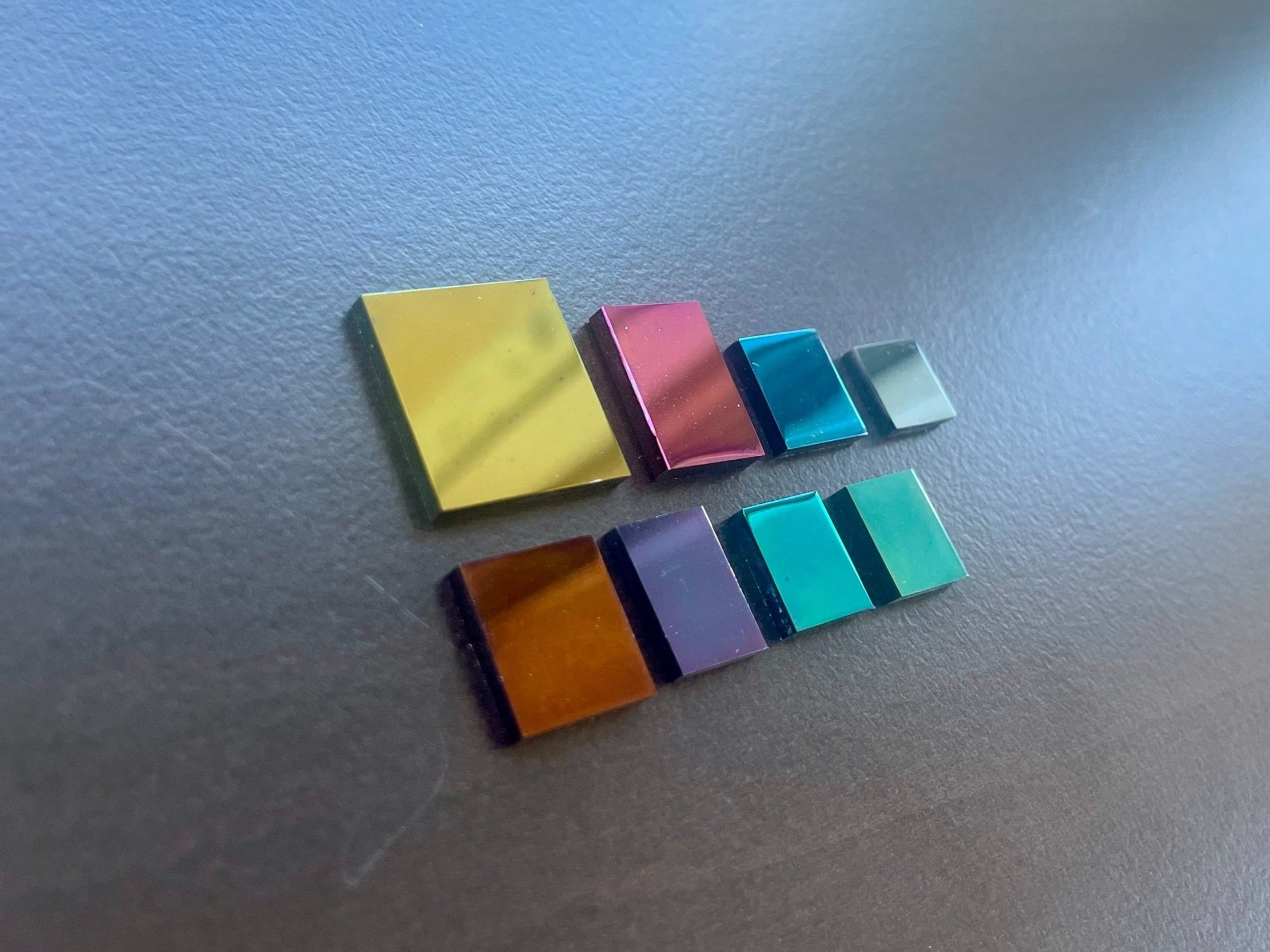

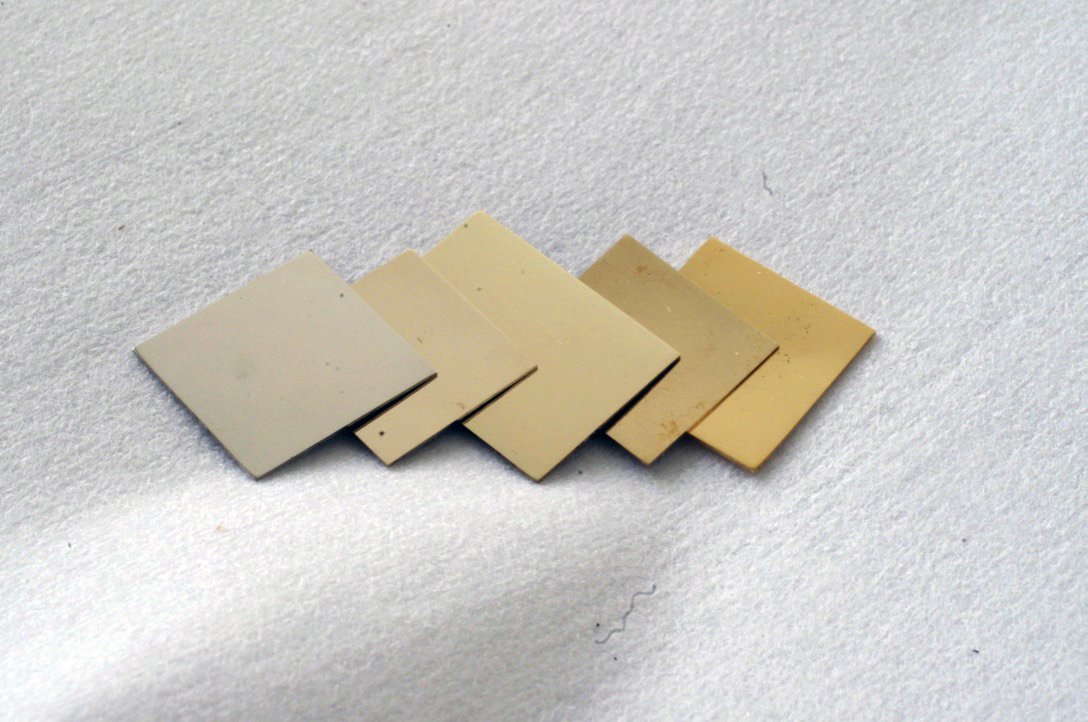

GlassiZirconium

GlassiZirconium is a beryllium-free zirconium-based metallic glass that has the "whitest" native color amongst zirconium-based metallic glasses. It may be conversion coated to achieve a wide range of colors in an ultra-hard wear-resistant coating. It is an attractive material for applications demanding engineering performance combined with cosmetic appeal.

Applications: consumer electronics hardware, exterior watch hardware, jewelry, eyewear, medical devices

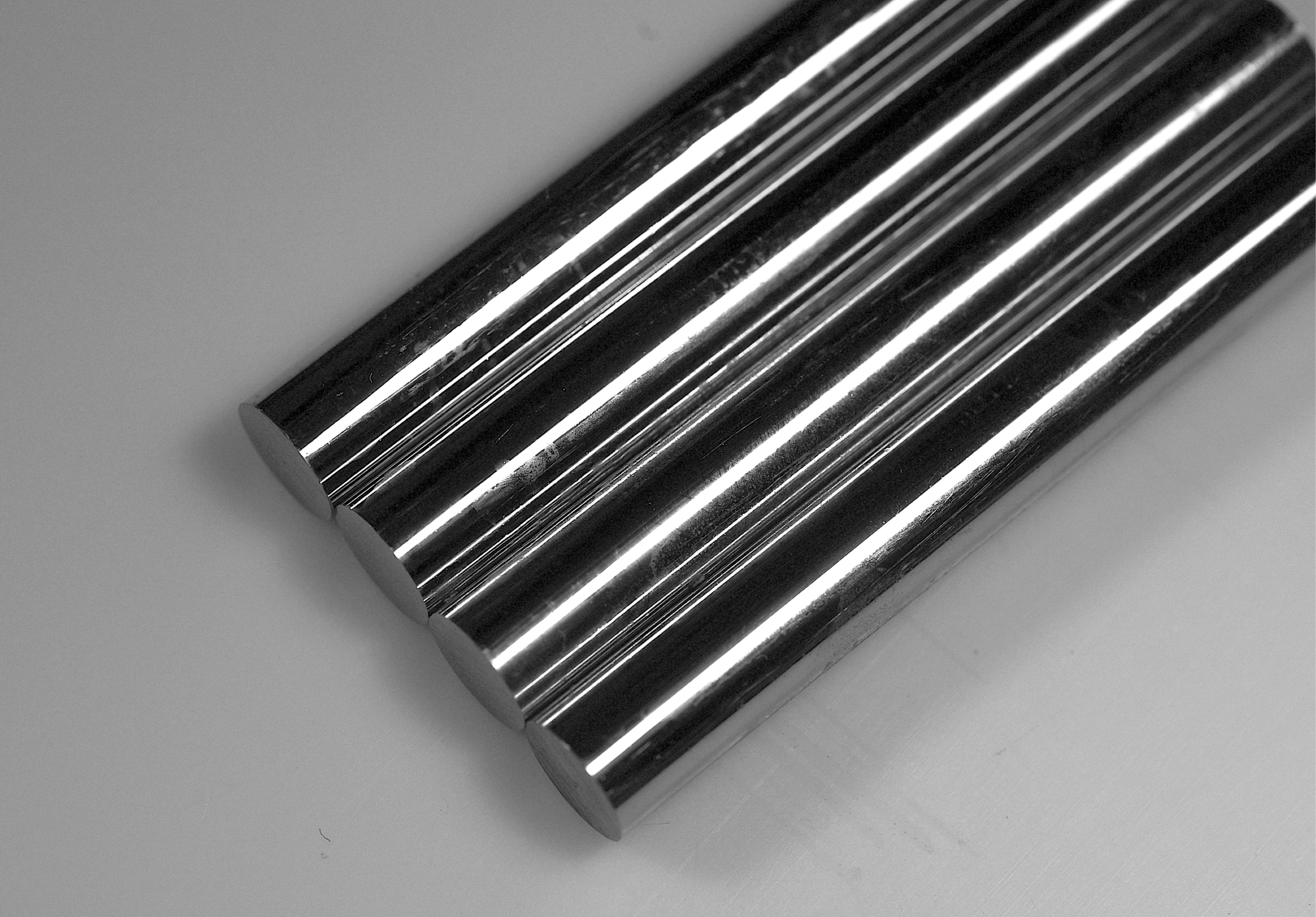

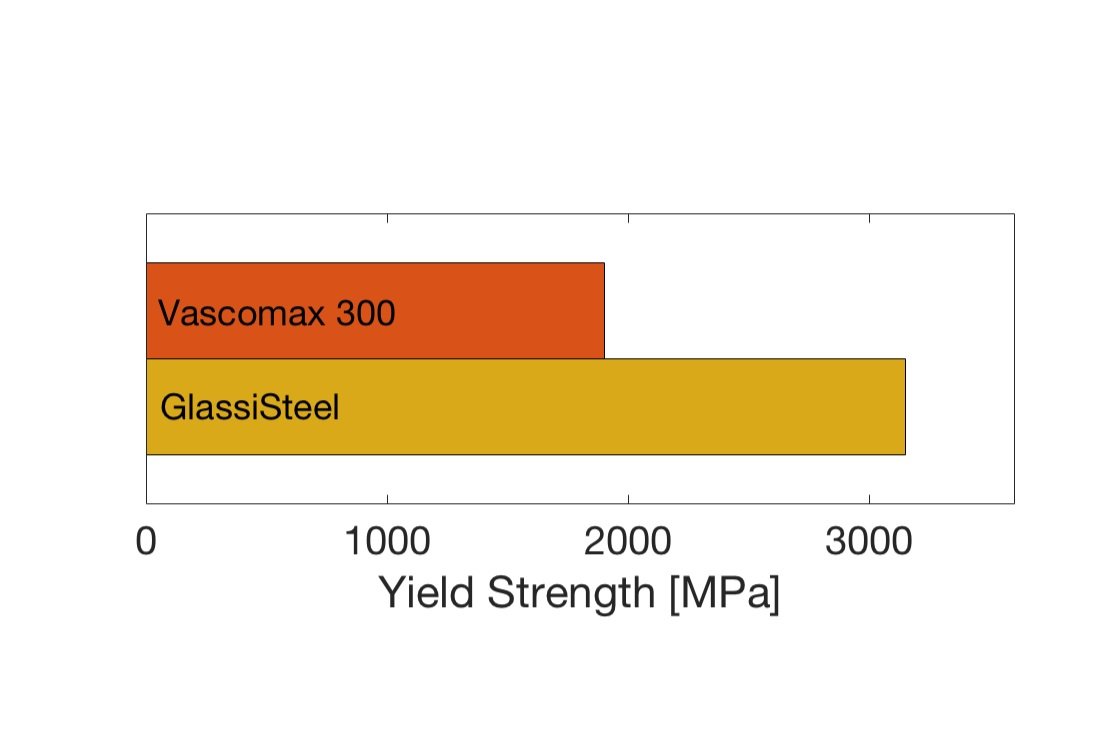

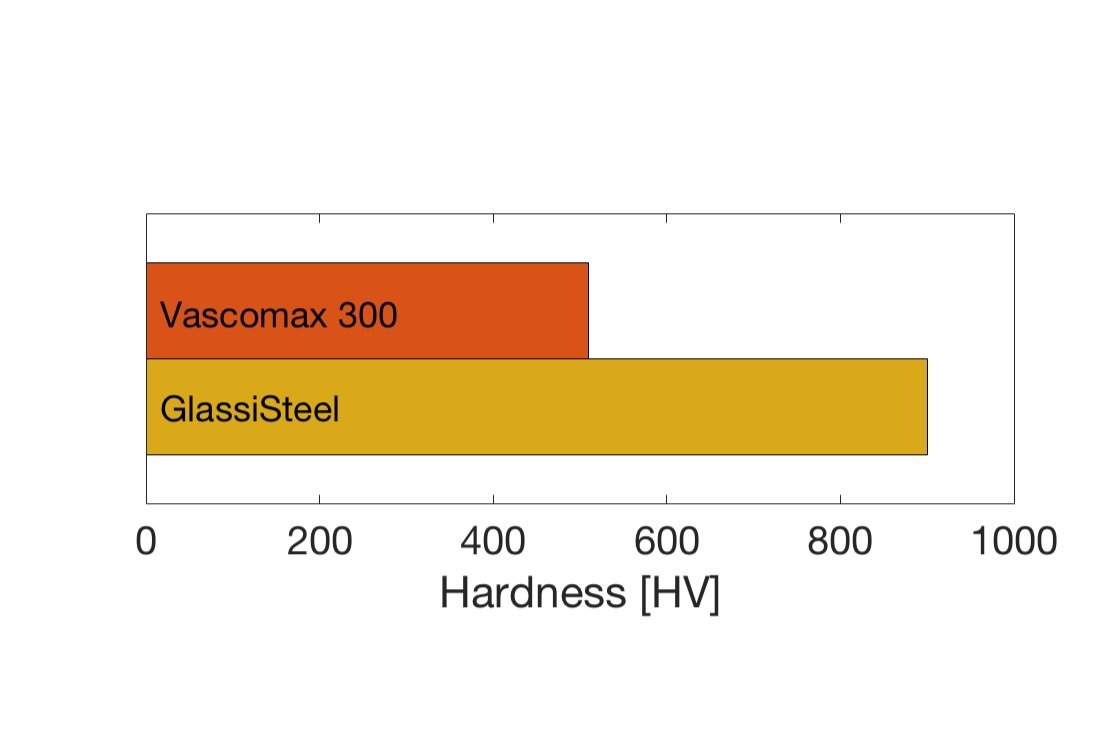

GlassiSteel

GlassiSteel is a low-cost stainless-steel metallic glass offerring ceramic-like wear and scratch resistance. GlassiSteel is tailor made for commodity hardware requiring wear and scratch performance, and may be effectively spray coated on conventional steels.

Applications: mechanical tools, civil construction hardware, agricultural hardware, mining hardware, marine hardware

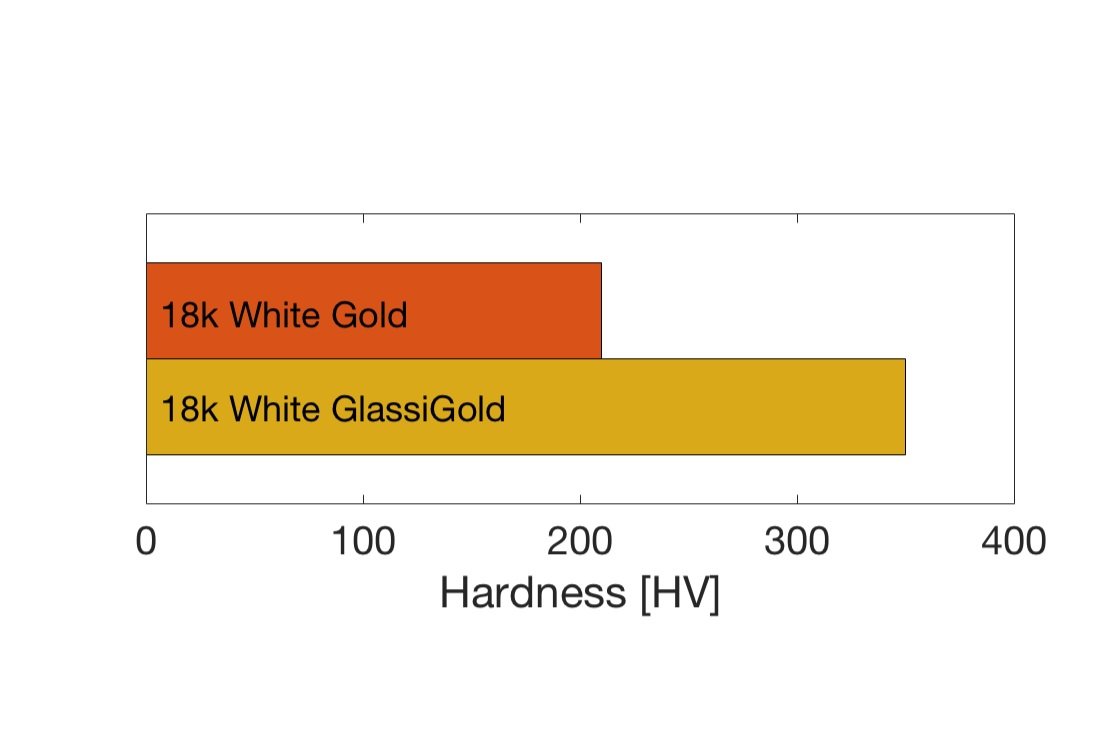

Precious Alloys

Glassimetal’s proprietary precious alloys meet standard jewelry hallmarks and offer distinct advantages over conventional precious alloys including hardness, wear and scratch resistance, corrosion resistance and cosmetic appeal.

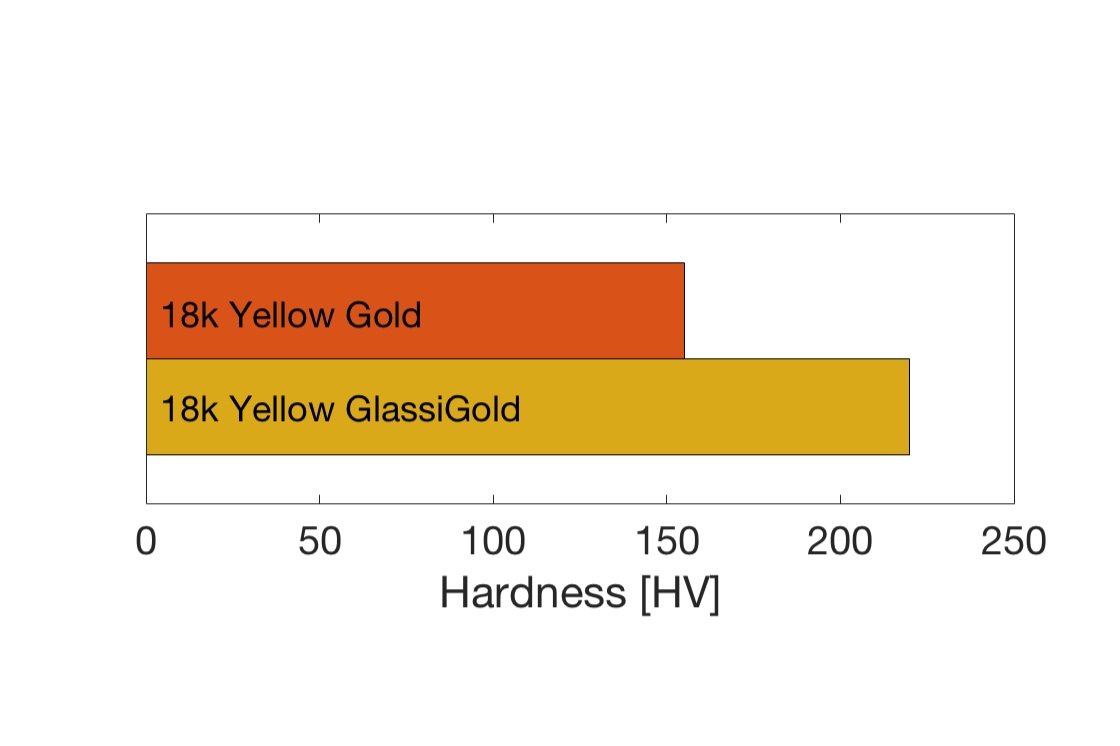

GlassiGold

GlassiGold is a metallic glass gold alloy that meets the18-karat hallmark and features white and yellow variants. Owing to a proprietary microstructure, the color of GlassiGold may be tuned within a broad range of yellow colors. With wear and scratch resistance outperforming conventional 18k gold alloys, GlassiGold is ideally tailored for durable luxury goods.

Application: jewelry, watches, medical devices

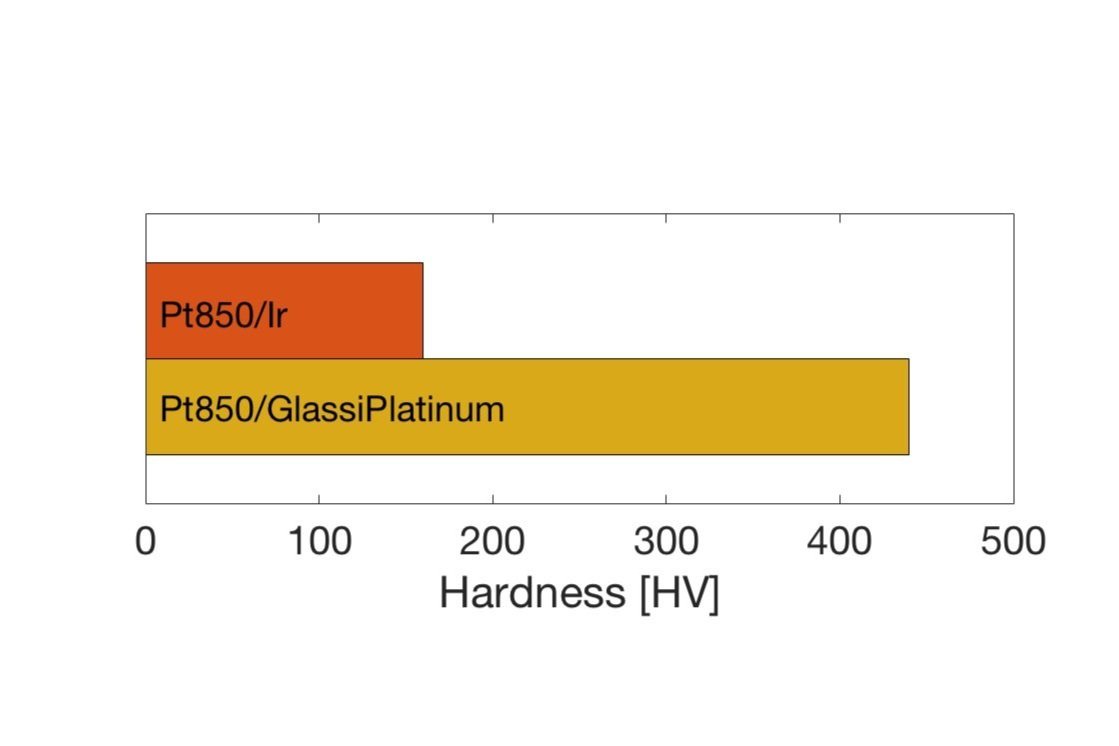

GlassiPlatinum

GlassiPlatinum is a platinum metallic glass meeting the Pt850 and Pt950 hallmarks. Free of nickel, highly processable, and with hardness 2 to 3 times higher than conventional platinum, GlassiPlatinum is poised to disrupt the platinum luxury market.

Application: jewelry, watches, medical devices

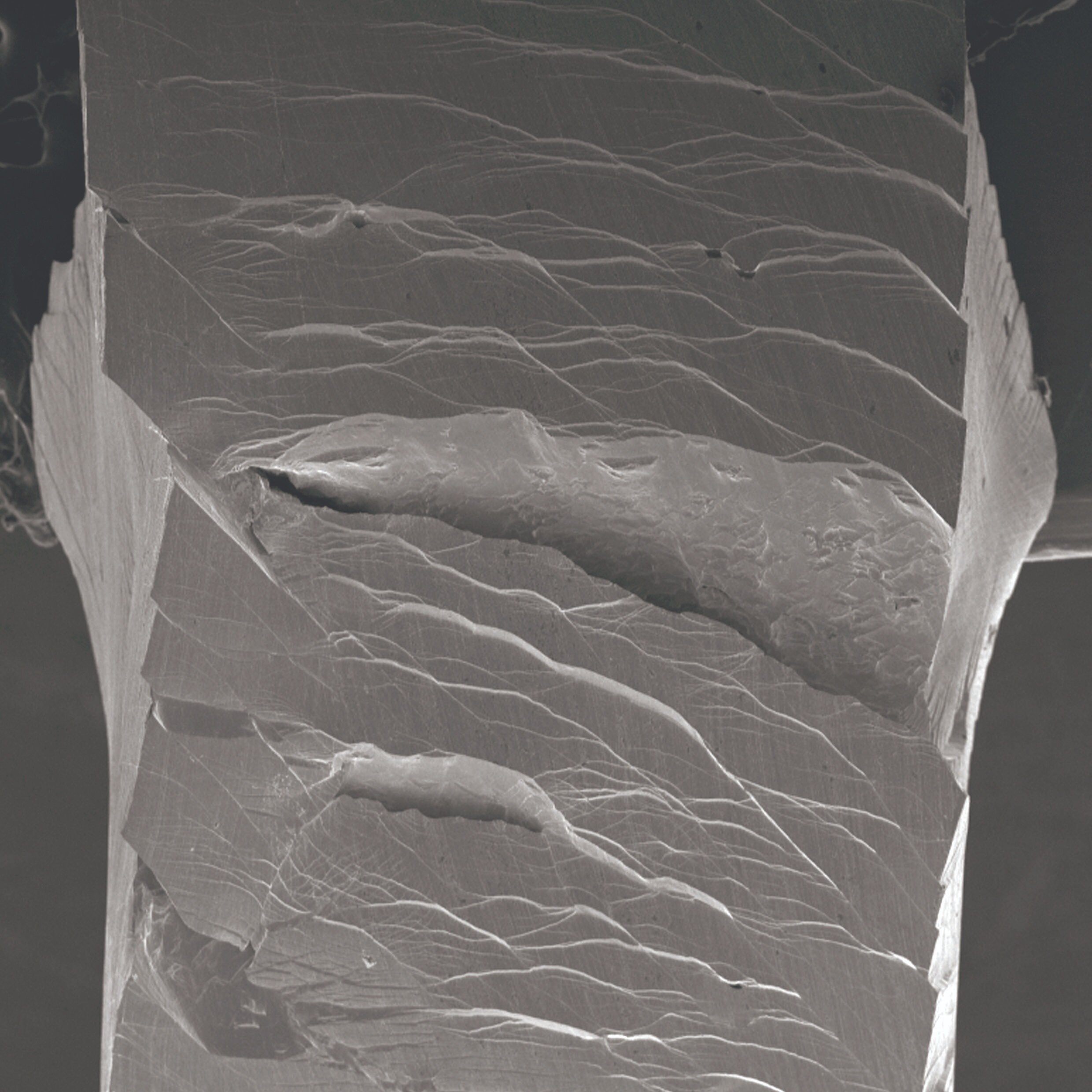

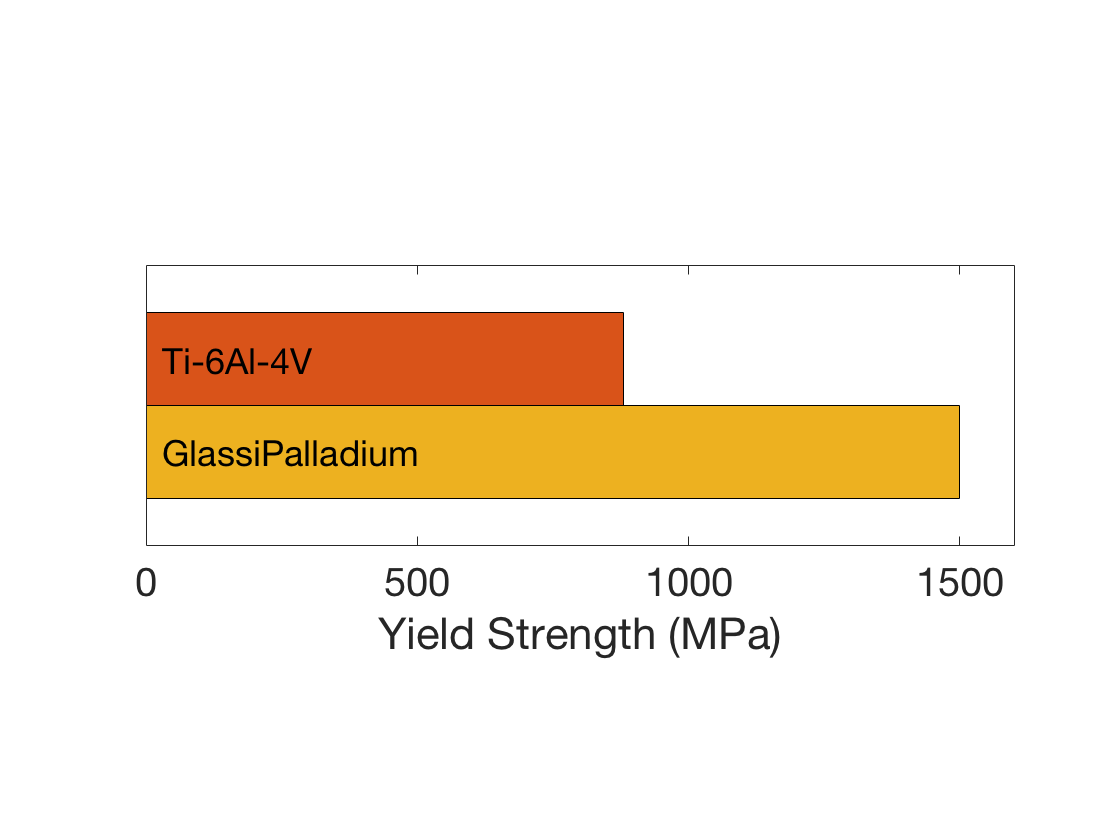

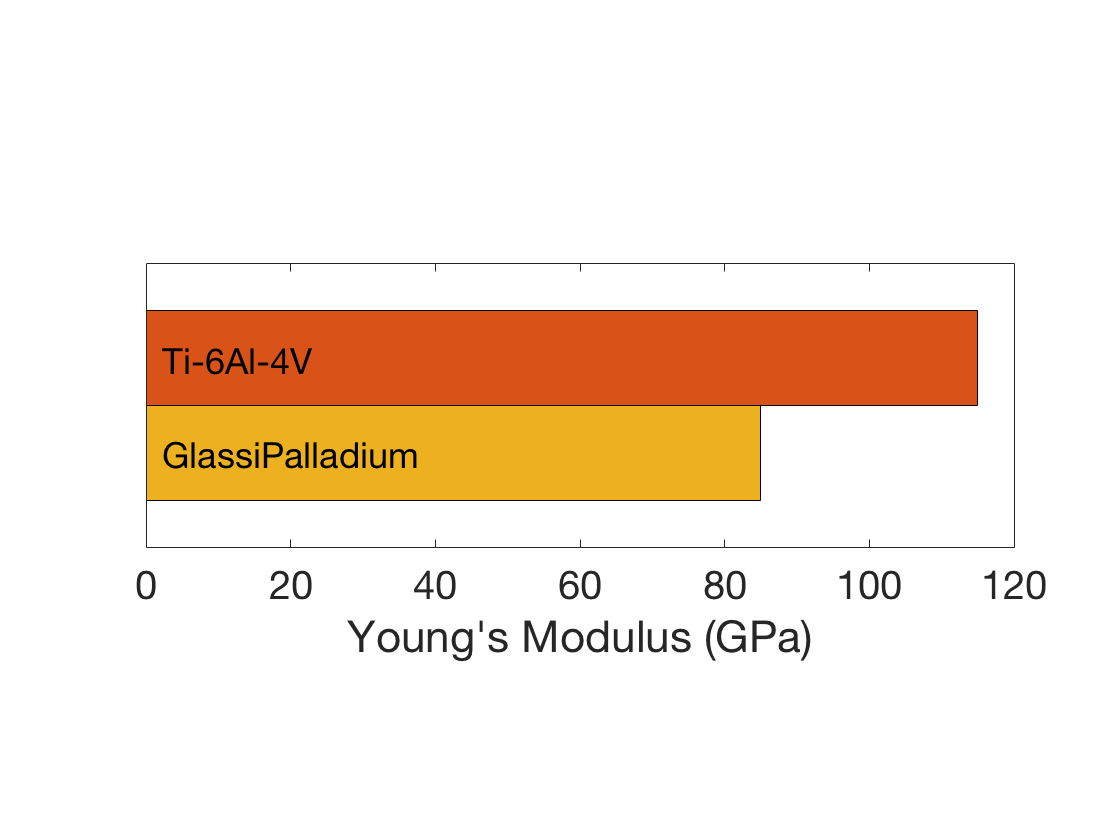

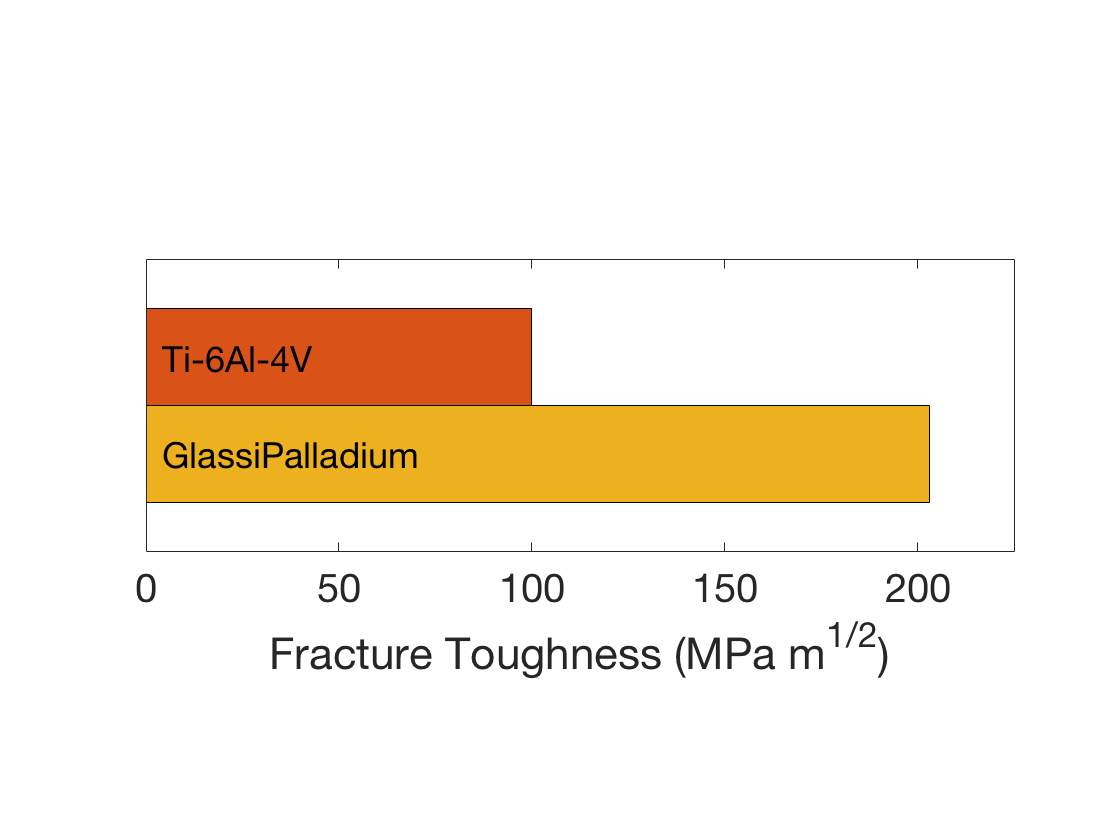

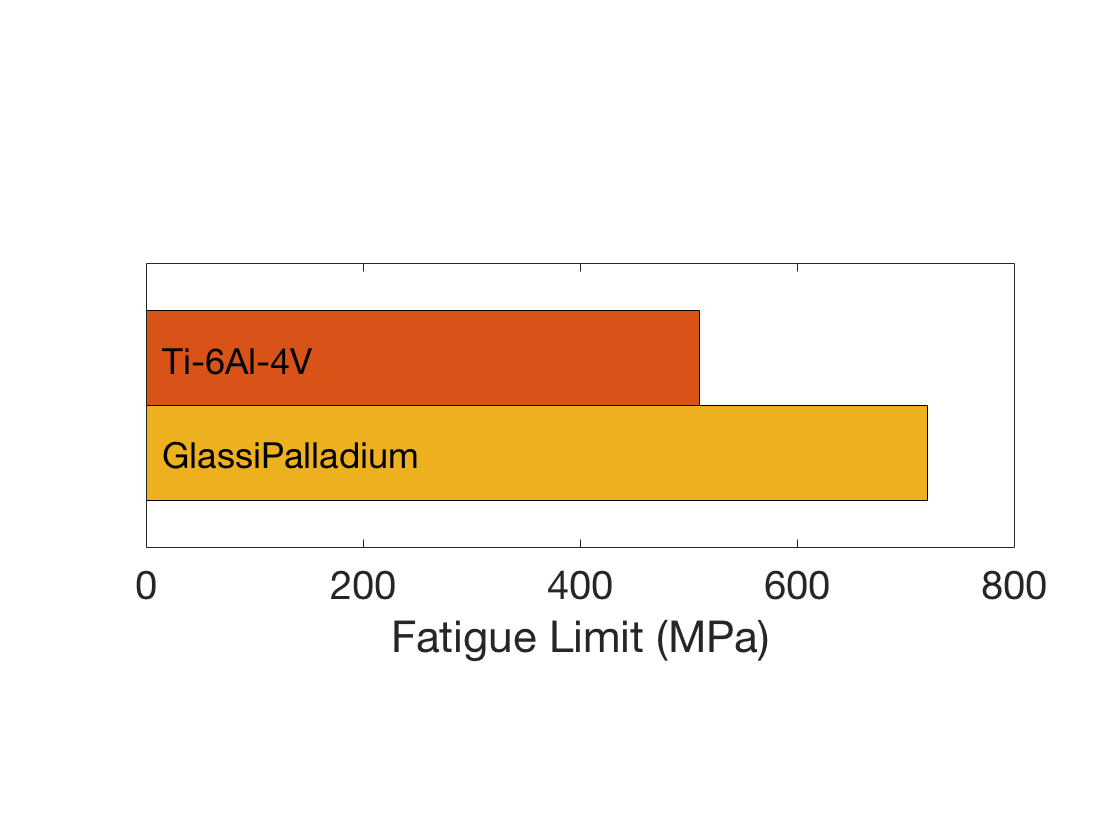

GlassiPalladium

GlassiPalladium is a metallic glass based on palladium with 50 and 90 weight percent variants. GlassiPalladium offers an unusual combination of high strength and toughness that promote an unparalleled damage tolerance. Along with its highly noble and inert chemistry, GlassiPalladium is uniquely cut out for applications demanding performance under complex mechanical and corrosive loads.

Application: dental implants, trauma fixation devices

Metallic Glass FAQ's

When was it invented?

In 1960, Pol Duwez and his group at the California Institute of Technology reported the first Au-Si liquid-metal alloy to be vitrified by cooling from the molten state. These metallic alloys require cooling rates of 1,000,000 degrees per second to suppress crystallization and form a metallic glass, thereby limiting the specimen geometry to micron-thin sections.

How is it formed?

Unlike conventional glasses (e.g. silicate glasses), metallic glass cannot be found in nature as it cannot evolve by a natural process. It is a frozen metallic liquid lacking crystallinity, and can only be processed in the laboratory. Such unstable amorphous configuration is permanently locked in the solid state by cooling from the melt with sufficient celerity to suppress formation of the stable crystal until the melt completely loses its fluidity.

What are the benefits?

Metallic glass is an emerging class of metals that exhibit unusual properties attractive for advanced engineering hardware applications.

These properties include a near theoretical strength and hardness, low damping, large elastic strain, very low solidification shrinkage, and the ability to be thermoplastically formed into precision net shape hardware of complex geometry, all of which are superior to traditional crystalline metal alloys.

"GlassiNickel is 2 to 3 times stronger and harder than high strength steel and titanium alloys."

- Bill Johnson, Glassimetal Technology

Compared to its conventional crystalline counterparts, the exceptional properties of metallic glass enable design of components with better performance, smaller footprints, greater complexity, and enhanced precision and tolerance.

What are the notable recent developments?

For the past 30 years it is known that metallic glass can be directly produced in bulk 3-dimensional geometries by uncovering unique compositions that may be vitrified at relatively low cooling rates. In the early 1990's, Prof. William L. Johnson and his group at the California Institute of Technology developed Zr-based bulk metallic glass (BMG) that can vitrify with a cooling rate of just 1 degree per second, thereby allowing casting of amorphous parts with cross section thicknesses in the order of centimeters.

Shortly after, the Zr-based BMG was commercialized and is in use today in several commercial applications due to its unique engineering properties.

Due to rather high raw material and processing costs compared to mainstream metals such as steel and aluminum, the Zr-based BMG is deemed rather "exotic". Recently, new ferrous-metal BMGs based on iron and nickel bearing chromium have been developed with material cost structures similar to those for conventional engineering alloys. Precious metal BMGs made of Platinum, Palladium, and Gold have also been recently introduced intended for use in hallmarked jewelry applications.

What's is the next frontier?

The 21st century’s market for complex and copious consumer hardware demands a transformational shift in manufacturing that meets a high bar for environmental sustainability. The expanding metals manufacturing market, $4tr worldwide, creates an opening for a disruptive platform enabling scalable and sustainable production of precision and performance hardware. With an exceptional engineering material (metallic glass) and a revolutionary manufacturing platform (Rapid Discharge Forming), Glassimetal’s technology represents a new paradigm in the manufacturing of advanced engineering hardware.